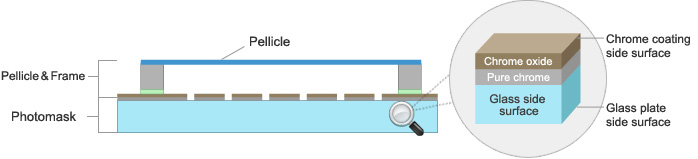

A photomask is a glass plate with pattern (i.g. electric circuits) chrome etched on a side. The chrome is applied only on one side of the glass plate. Anti-dust protection cover called pellicle is applied if required. In most of the cases, the chrome is double layered with pure chrome and chrome oxide that prevents the light reflection.

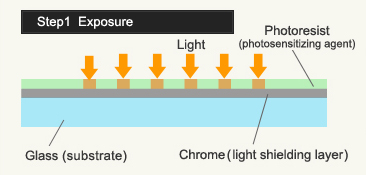

Photomask patterns are created with chrome on the designated area. Laser beam exposure is applied according to the design data on a glass substrate covered with chrome and photoresist layers. Then, it goes through development and etching steps to complete the patterning. NIPPON FILCON is using positive-type photoresist, thus the laser-beamed area shall be removed during the development process. The area shall be etched and appears as a clear area.

Based on the design data, apply laser beam to the designated area for the photo resist to be exposed.

For positive type photo resist, by being exposed to the light, the photo resist coating of the exposed area is removed by the exposure process.

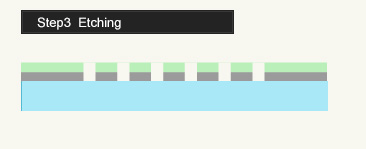

Chrome area on the revealed surface is removed by etching.

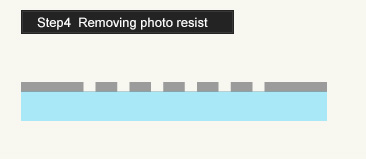

Remove the remaining photo resist on the chrome. After rinsing, the photomask pattern is completed.