NIPPON FILCON FineElectronics In-House Company has invested in production equipment to build up its production since its foundation in 1981. We have manufactured reticles and master & copy masks for semiconductor devices as its primary products. Our photomasks are widely used in the area of electronics devices, such as integrated circuits, power devices, discrete devices, laser diodes, LCDs/ OLEDs, optical waveguides, LEDs, and various scales. Photomasks are required to turn the product designs into actual products.

We are responsible to enhance human society with our photomask technology.

NIPPON FILCON employees take pride in our work, ensuring daily inspection and challenging to new technology with great passion and persistence. They are motivated individuals with ambition for innovations to make people’s life better. That is where our engineering always starts from and the employees and the technologies are what we treasure.

NIPPON FILCON FineElectronics In-House Company strives to improve our technology and service to our customers based on the following philosophies:

![[Being sincere.][Being customer-oriented.][Returning the received good will to the society.]](/en/about-us/image/jg_img06.jpg)

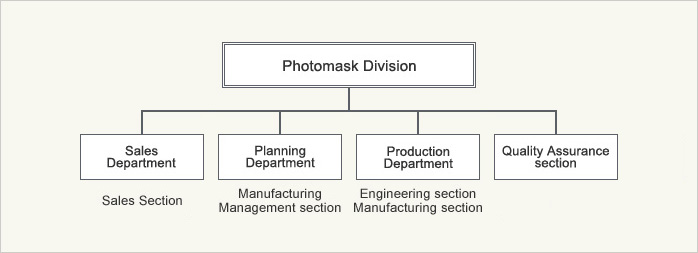

Photomask division consists of five departments as shown in the organization chart below.

- 1936Founded as NIPPON Wire Cloth Co., LTD.

- 1972Changed corporate name to NIPPON FILCON CO., LTD.

- 1982Micro Products Division started photomask manufacturing

- 1998Installed Micronic LRS200

- 2001Installed Micronic OMEGA

- 2008Expanded clean-room and installed newest Micronic OMEGA

- 2010Established Photomask Division