- A photomask is tool used for productions of components including electronic devices (semiconductors), displays, PCB, MEMS. It is a master copy for the patterning.

- Photolithography is used to form PCB circuits and display patterns. Photomasks are used to transfer the patterns on the baseplates.

- A photomask acts just like "negative film" in photography, and that makes the baseplates "printing paper".

- Electronic devices - CPU, memories (semiconductor/ IC)

- Discreet components with a single task - transistors, memories

- Light receiving/ emitting elements - CCD/CMOS image sensors, LED

- PWB - motherboards

- Display devices - LCD, OLED

- MEMS(Micro Electro Mechanical System) - acceleration sensors

- Magnetic heads for hard disks

- Heads for inkjet printers

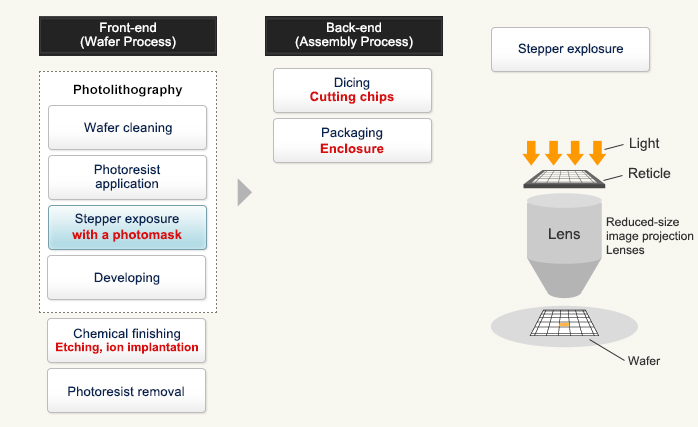

A reticle is usually used in the front-end process of semiconductor fabrication.

A pattern to be transferred to silicon wafers is produced by chrome etching on a glass plate. The pattern is transferred to wafers through an exposure device.

- Front-end process is a process to form circuits on wafers to be made into semiconductors.Reticles are used for prior processing for the exposure process.

- Back-end processing is an assembly process that includes dicing (cutting the wafer into chips) and packaging (protection) after forming the circuits.

- A stepper is an exposure device used for semiconductor fabrication. It transfers a design on the reticle to wafers by light with wavelength matching the circuit line width.