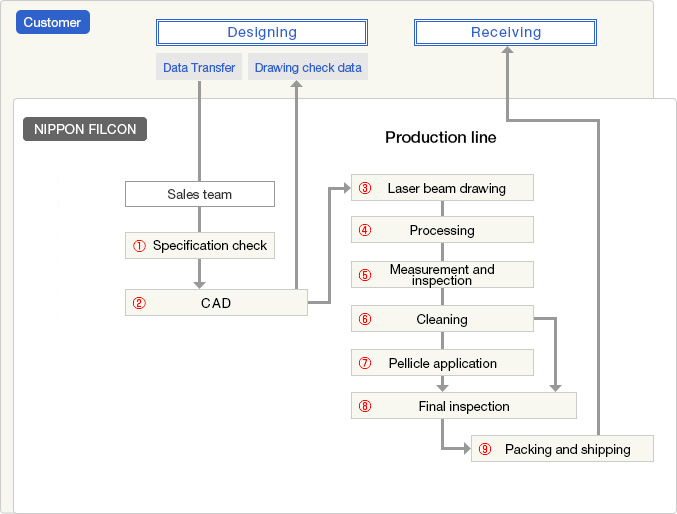

There are CAD, drawing and processing, inspection & measurement cleaning , pellicle processing steps.

- Photomask production starts after receiving and checking the CAD data and the specification received.

- After drawing check in CAD process, we send the check data in PDF or other formats to the customer for confirmation.

- After the customer's approval, it goes on to the production line.

- Through the processing step, it goes through development, etching, photo resist removal, cleaning and drying processes.

- Pattern measurement and cosmetic inspection.

- All masks go to cleaning step.

- Some of masks mount pelicle,and then particle inspection.

- Final inspections for check items including the specification, criteria, surface.

- Packing and shipping